Walk through any of the Technion’s campuses, and you’ll find dozens and dozens of faculty members dedicated to research projects that push the boundaries of their fields.

The Technion is committed to making sure research that can change the world reaches consumers as quickly as possible.

Technion Technology Transfer (T3) is the unit that identifies the most promising research and helps bring it from the lab to the marketplace. T3 helped commercialize a drug for early-stage Parkinson’s, known as Azilect to consumers. And the new Innovation and Entrepreneurship Center, or T-Hub, serves as an umbrella for entrepreneurial ventures that encourage students and faculty members to think bigger and bolder about how their research can be applied.

It’s no wonder 2019 was a record-breaking year for Israel’s economy. Thanks to the Technion’s efforts to nurture entrepreneurs and bring their research to life, Israel is seeing more venture capital revenue, more exports, and double the number of “unicorn” businesses — privately held companies with a valuation of $1 billion or more.

Here are just a few of the researchers and breakthroughs powering this economic revolution.

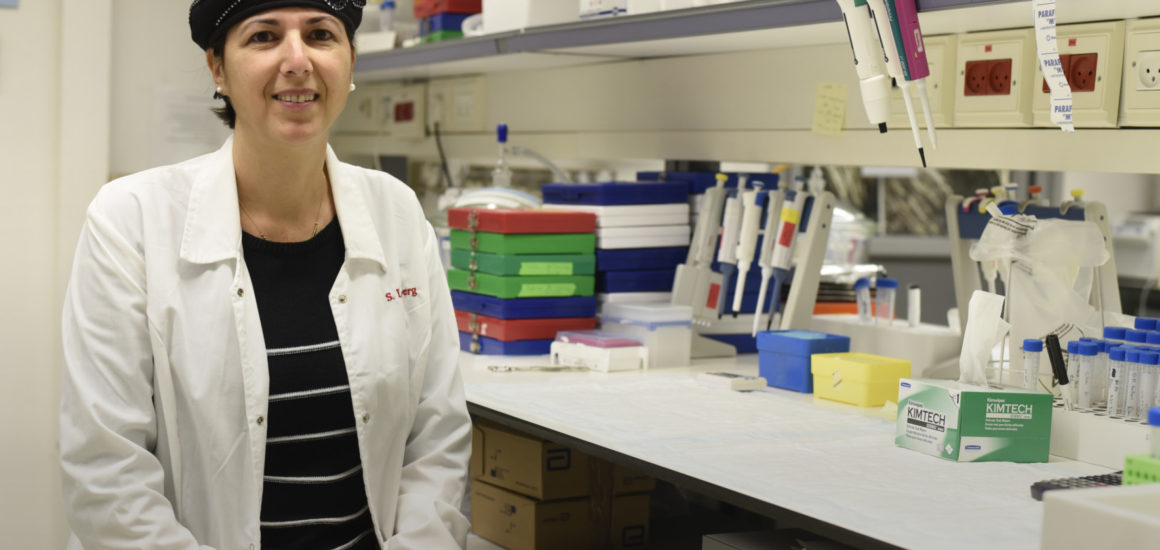

Professor Marcelle Machluf and NanoGhosts

Shrinking tumors from within

The dean of the Faculty of Biotechnology and Food Engineering at the Technion, Prof. Machluf launched her own startup earlier this year to market what she calls NanoGhosts.

Despite medical advances, brain tumors — particularly those originating from metastatic melanoma — have a grim prognosis for patients. Experts have long struggled with how to deliver therapeutic agents safely to the brain.

Prof. Machluf has created a novel targeted drug carrier, made from the outer membrane of human mesenchymal stem cells. These stem cells have been found to stick to cancerous cells and help them hide from the immune system, enabling tumor cells to grow unchecked. By emptying these stem cells of their content, rendering them “ghosts,” shrinking, and loading the new nanosized cell membrane with cancer-fighting drugs, these cells can be injected into the bloodstream. From there, they merge with the tumor, delivering medication that kills cancerous cells from within.

Animal trials of NanoGhosts have been extremely impressive thus far. One injection led to an 80% to 85% reduction in tumor size. Prof. Machluf is adapting NanoGhosts to pass the blood–brain barrier and has started to look at the technology for possible use in lessening the level of infection in COVID-19 patients.

Two years ago, the Israel Science and Technology Ministry named Prof. Machluf’s research as one of Israel’s 60 most impactful developments.

Professor Shulamit Levenberg and Aleph Farms

Lab-grown meat that tastes like the real thing

Prof. Levenberg, dean of the Faculty of Biomedical Engineering and the Stanley and Sylvia Shirvan Chair in Cancer and Life Sciences, used her expertise in tissue engineering to develop an innovative solution to the looming food crisis: real steak grown from cow cells that avoids killing animals and significantly reduces the impact on the environment.

Her lab-grown meat begins with isolating the cells responsible for regenerating and building muscle tissues in cows. Prof. Levenberg then uses a proprietary 3D platform to grow the cells and develop a beef product that is close in taste, texture, and structure to the real thing.

Unlike meat substitutes that are plant-based, Prof. Levenberg’s meat comes from beef cells — just with a dramatically lower environmental and more humane footprint. And because the meat is grown in the lab, there’s no need for antibiotics, reducing the risk of foodborne illnesses.

This research has been developed into the highly successful startup Aleph Farms, where Prof. Levenberg serves as the company’s chief scientific officer. Last year, it raised nearly $12 million in financing to expand its work even further.

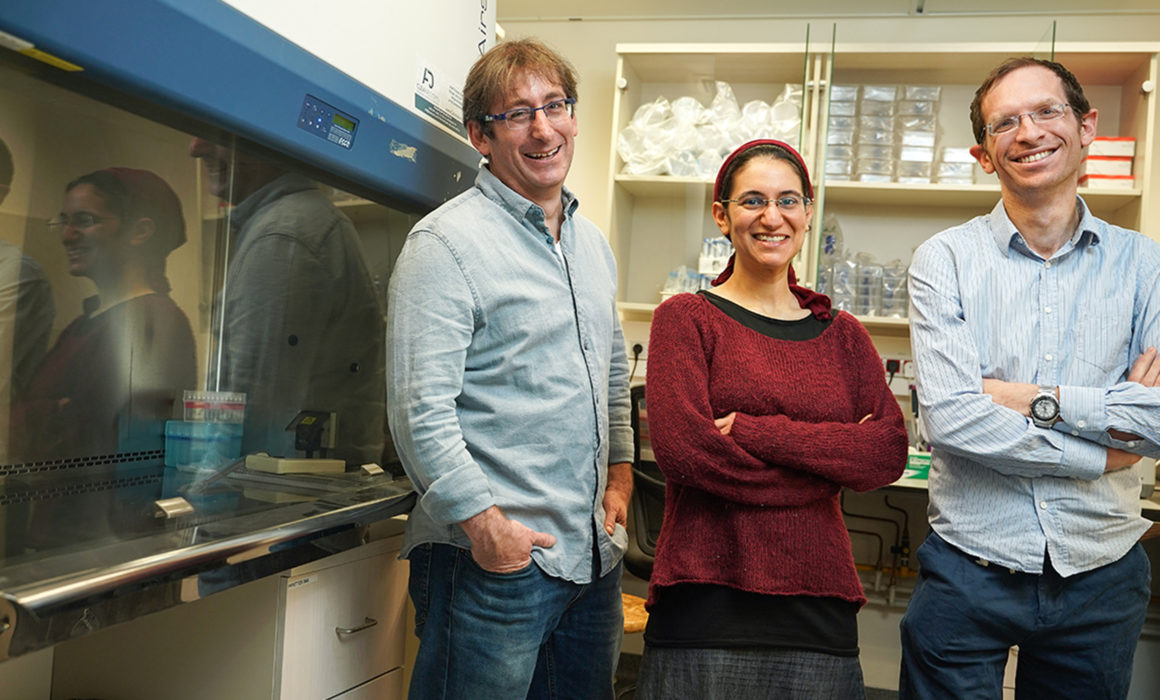

Associate Professor Shai Shen-Orr and CytoReason

Big data meets biology

Many drugs tested successfully on mice fail in human clinical trials. And even when clinical trials are successful, they can be extremely lengthy and expensive. Prof. Shen-Orr, head of the Technion’s Systems Immunology and Precision Medicine Lab, has a solution.

By bringing together big data with biology, Prof. Shen-Orr is able to predict how an individual will react to a particular drug and develop a personalized medication. CytoReason is the world’s first and only machine-learning platform that can map someone’s immune system at the cellular level and understand how they will react to different diseases — and treatments.

CytoReason could revolutionize cancer immunotherapy as well as autoimmune, neurodegenerative, and infectious disease research by making research more efficient and delivering more personalized treatments. Prof. Shen-Orr and CytoReason are currently collaborating with top global pharmaceutical companies like GlaxoSmithKline and Pfizer, as well as the U.S.-based Parker Institute for Cancer Immunotherapy.

Prof. Shen-Orr has also developed a way to gauge an individual’s “immune age” — a more accurate measure of health than chronological age that can better pinpoint one’s risk for infection and chronic diseases such as cancer and heart disease.

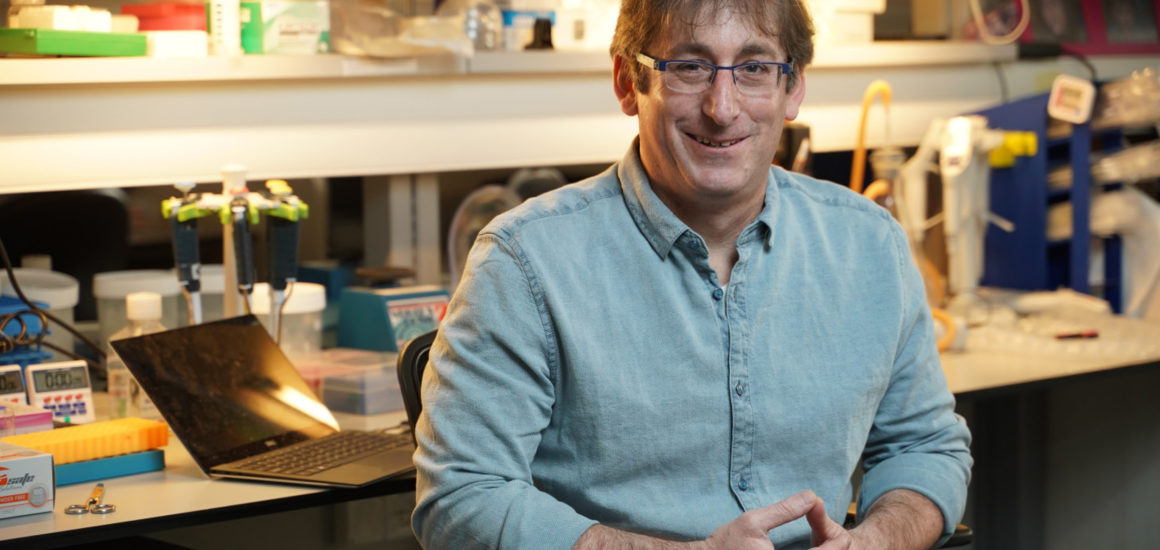

Professors Gideon Grader and Avner Rothschild with Dr. Hen Dotan and doctoral candidate Avigail Landman: H2Pro

Greener, efficient energy

Technion researchers at the Nancy and Stephen Grand Technion Energy Program have developed a new hydrogen production technology that is greener and would improve production efficiency from 75% to 98.7% as compared with hydrogen production from natural gas.

Most hydrogen produced today is used in fertilizers and refineries. But as the world moves toward cleaner power sources, hydrogen will play a huge role as a renewable energy source for powering our electric cars and heating our homes.

The Technion team’s technology uses electrochemical–thermally activated chemical (E-TAC) water splitting to generate hydrogen. E-TAC decouples the hydrogen molecules from the oxygen molecules. Since the process happens through a spontaneous chemical reaction rather than an electrical current, the process is much more energy efficient. It’s cheaper, too: Researchers expect the cost of equipment to produce hydrogen through E-TAC will be about half of that used in existing technologies.

H2Pro was created to commercialize this innovative hydrogen production technology. The company was given an exclusive license by the Technion to commercialize the product and to date has raised nearly $5 million in a campaign led by Hyundai.